By: Bruce Reinstein | January 18, 2024

Staying on top of your business minimizes the impact.

Convenience store foodservice operators are coping with inflation in different ways, but it is the consumer that has had to make serious adjustments to their spending habits. It is up to operators to provide their customers with quality options at a manageable price.

This is something that is quite doable as long as the operator is open to making changes that will not affect the size of the portion or quality of the product. Consumers have gotten very educated from these tactics and value is their main focus when it comes to a positive experience.

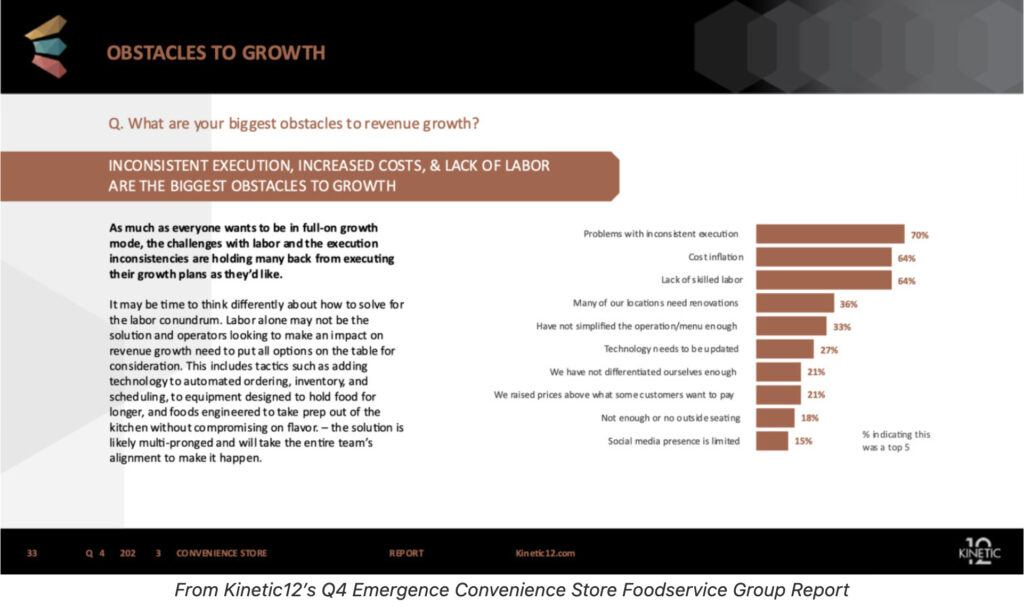

Operators look at cost inflation as the No. 2 biggest obstacle to revenue growth.

Here are six strategies for coping with inflation in c-store foodservice.

1. Do not use inflation as an excuse for reduced profitability.

The foodservice industry has always had ups and downs when it comes to cost inflation. This relates to food and beverage, packaging, staffing and all other costs. There is a tendency to dwell on the negatives and look at those as the reason you can’t be profitable.

Inflation should become the impetus to driving new revenue and creatively adjusting costs. Consumers have a choice as to where they go, and those operators that focus on consistent execution, great speed of service, a welcoming environment with engaged team members and a mindset to avoid being transactional will be the winners in times of cost inflation.

2. Adjust your menu offerings to provide value at a manageable cost.

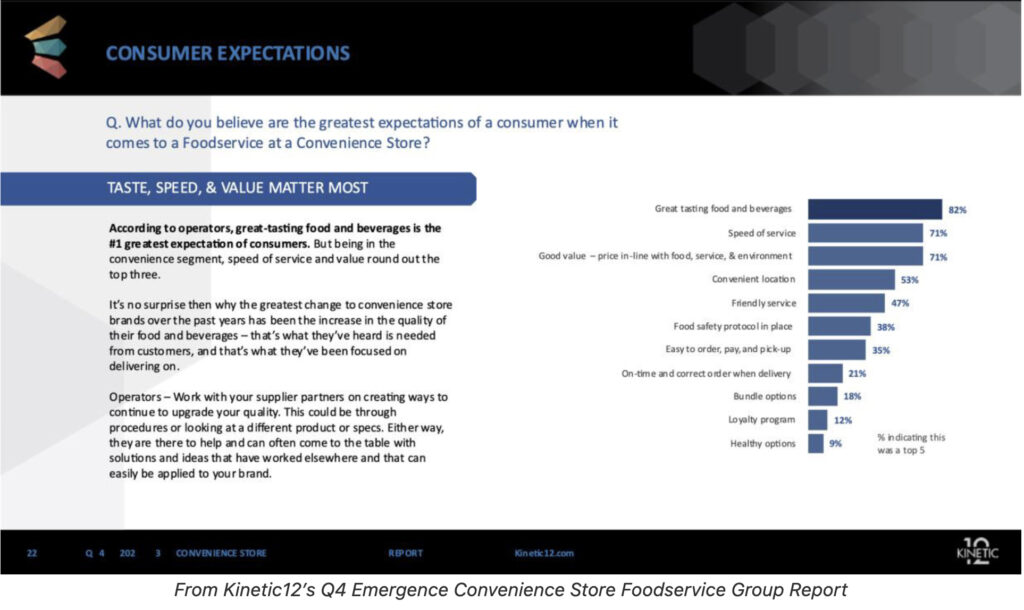

Convenience store foodservice customers are looking for great tasting food and beverages, speed of service, good value and convenience as their greatest expectations. To meet or exceed these expectations, operators must make some menu and operational adjustments. Having a balance of meeting customer expectations and being profitable has challenges but is very doable.

It starts with the menu. What is selling, what is not selling and what are customers craving? What is the cost structure of all of these items and are there menu items that are complicated to prepare and take too long for the customer to get? Is there a grab-and-go program that provides customers with the opportunity to get what they want at a faster pace?

These are questions that have to be asked constantly, and adjustments that have to be made quickly and efficiently. While doing this, it is crucial to avoid reducing quality or portion size.

3. Work closely with your manufacturer and distributor partners.

Foodservice operators must lean on their manufacturer and distributor partners. Many of them have the capabilities to support operators through culinary, marketing and data. They also have the knowledge to support cost reduction by providing alternative products at a better price that match the quality standards of the operator’s business. In addition, supplier partners can provide labor savings options, including speed scratch and par baked items.

It is important to challenge your manufacturer and distributor partners. They have many solutions to potential cost inflation problems.

4. Focus on staff engagement and create a winning environment.

A great team can only be attained with great leadership. The cost of labor is higher than it has ever been, but with solid productivity and limited turnover, higher labor costs can have minimal effect on the bottom line.

Convenience store foodservice operators can minimize the cost of labor by cross training their teams and avoiding just filling slots with “bodies.” Creating an excellent work-life balance for team members and management, along with making going to work fun, will not only be positive for the staff, but also for customers.

Staff engagement is crucial to success. Leadership must value their thoughts and recommendations to keep them focused on doing a great job and making a difference in the customer experience.

5. Improve execution to create better consistency and less waste.

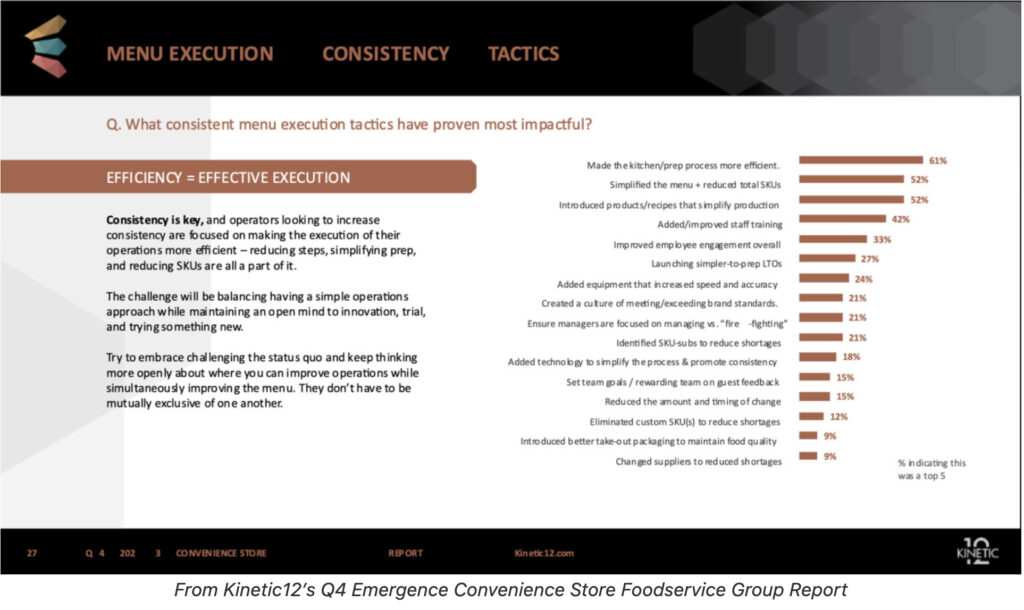

Great execution starts from the time the delivery truck comes to your door.

Refrigerated and frozen products must be put away quickly and efficiently with proper rotation to avoid waste. Prep in the kitchen should be simplified and speed scratch products, as well as further processed ingredients such as broccoli florets, should be added. It may appear to be more expensive, but reducing labor, throwing less useable products in the trash and being more consistent will ultimately lower costs.

The same holds true with the production of menu items. Keeping it simple and having great training will have a positive effect on the execution of what the guest has ordered. It will also bring them back more often.

6. Don’t be afraid to make changes.

There is a tendency to protect the “sacred cows.” Most of the time, these menu items are not as popular as you would think and, in many cases, they are not as profitable as other items.

The consumer has changed, and operators must change with them. This involves making it easier for customers to order, pay and pick-up, as well as providing the type of menu selection and value proposition that will keep them coming back.

The consumer wants quality food and beverage with great service. They also want it that way every time. It seems like a daunting task, but if operators are willing to adjust, they can appease the desires of their guests and in the long-term, that means happy, loyal customers and greater profitability.

Bruce Reinstein is a partner with Kinetic12 Consulting, a Chicago-based foodservice and general management consulting firm. The firm works with leading foodservice operators, suppliers and organizations on customized strategic initiatives as well as guiding multiple collaborative forums and best practice projects. Join the Emergence Convenience Foodservice Group and get two detailed reports per year and the potential to attend Kinetic12’s April and November foodservice forums. For more information: Kinetic12.com or [email protected].

Source: CStore Decisions